Industrial Scales for Precision: Enhancing Reliability in Manufacturing Lines

Industrial Scales for Precision: Enhancing Reliability in Manufacturing Lines

Blog Article

A Comprehensive Overview to the Different Sorts Of Industrial Scales Available Today

The industrial landscape is teeming with diverse evaluating needs, necessitating a myriad of range types. From durable system scales to precision-based counting ranges, each alternative provides to distinct needs, providing unequaled precision and performance. Agricultural scales.

Recognizing the Significance of Accurate Considering in Industries

In the vast realm of industrial operations, the relevance of exact considering is frequently taken too lightly. It plays a crucial role in maintaining quality, making sure safety and security, and enhancing efficiency. Industries such as drugs, food and beverage, or logistics rely heavily on precise weight measurements.

Mistakes in considering can lead to disastrous consequences. Inaccurate weight information can compromise product quality, resulting in non-compliance fines or pricey recalls.

Precise evaluating ensures optimum utilization of resources, decreasing waste and thus, shielding the atmosphere. It also enhances performance, as workers spend less time correcting errors.

Precision in weighing is not just concerning having advanced scales. It additionally entails normal calibration and maintenance of these ranges, in addition to training employees to use them correctly. Therefore, recognizing the relevance of exact weighing is basic to commercial success.

A Summary of the Various Sorts Of Industrial Scales

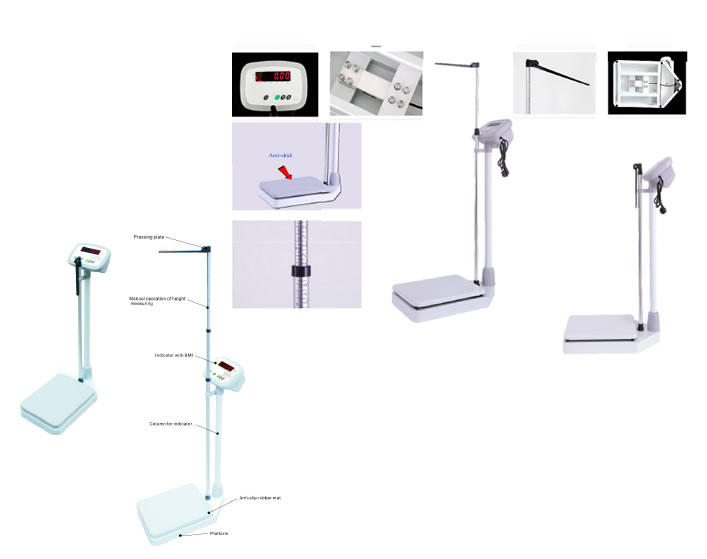

While there is a substantial variety of commercial scales available on the market, each type serves specific demands and applications. Amongst these are platform scales, which are typically used for durable applications because of their robust build and high weight ability. Bench ranges, on the other hand, are preferable for lighter loads and are usually utilized in labs and producing setups.

Another selection is the crane scale, developed for lifting and considering heavy things in industrial environments. Floor ranges, on the other hand, rest directly on the ground and are used for weighing big products that can be proceeded and off the scale using a pallet jack.

Counting ranges are one more type, typically used in supply monitoring to count large quantities of things quickly. Lastly, there are equilibrium ranges, providing exact measurements and commonly used in clinical and pharmaceutical applications. Each type has its own distinct attributes and advantages, created to fulfill a series of industry demands.

When Picking a Commercial Range, key Factors To Consider.

Picking the ideal commercial range for a particular procedure needs mindful thought and consideration. One have to examine the details requirements of their service, consisting of the weight variety of products to be gauged, the setting in which the scale will certainly run, and the accuracy called for.

The weight variety demand is important as commercial scales differ in their optimum abilities. A scale used for gauging huge deliveries might not need as much precision as one utilized for accurate chemical measurements.

Detailed Exam of the Leading Industrial Range Brands

Offered the wide variety of options offered on the market, reviewing leading commercial range click to read brands can be a difficult job. Nevertheless, some brands have set themselves apart via high quality, longevity, and progressed features.

One such brand is Mettler Toledo, a worldwide leader renowned for its precision and technical advancement. Their scales vary from small bench scales to durable vehicle scales, guaranteeing a remedy for every commercial requirement.

A&D Considering is an additional leading brand name, top article popular for its convenience in products and applications, while Fairbanks has earned recognition for its durable and trusted scales, specifically in sturdy applications. Agricultural scales.

Rice Lake Evaluating Equipments, on the other hand, provides a variety of scales, understood for their top quality building and construction and accuracy.

Each of these brand names provides special advantages, making the selection depending on specific sector requirements and spending plans.

The Future of Industrial Considering: Technological Developments and Trends

As the globe becomes significantly digital, the future of commercial evaluating is set to evolve with exciting technical innovations and patterns. The assimilation of expert system and Internet of Points (IoT) are at the center of these developments, assuring to change the commercial evaluating landscape.

AI-powered clever scales, for example, have the ability to self-calibrate and carry out mistake checks, minimizing downtime and improving performance. These scales can additionally assess and interpret information, supplying beneficial insights that can drive procedure improvements.

At the same time, IoT technology is making it possible for remote surveillance of industrial scales. This not only reduces navigate to this site the need for hand-operated evaluations but additionally allows for real-time data collection and analysis. This can result in more reliable inventory management and anticipating upkeep.

With these innovations, the future of commercial weighing looks set to be more exact, effective, and automated, giving markets with vital information in real-time and improving total performance.

Verdict

From heavy-duty platform scales to careful checking ranges, each kind provides to particular evaluating needs. As technology advances, industrial scales proceed to progress, assuring even more accuracy and versatility.

The commercial landscape is abundant with diverse evaluating needs, demanding a myriad of scale kinds. From sturdy platform scales to precision-based counting ranges, each alternative caters to distinct demands, supplying unmatched accuracy and effectiveness.While there is a comprehensive range of industrial scales readily available in the market, each kind offers particular requirements and applications.The weight array need is vital as industrial ranges differ in their maximum abilities. From heavy-duty system scales to thorough counting scales, each kind provides to certain evaluating needs.

Report this page